1. A durable paint finish for years to come

With industrially pre-painted exterior cladding panels, a finished façade is built immediately. There is no need to paint the panels after installation and maintenance painting can wait up to 10-20 years. The panels are painted within 60 hours of planing, which ensures the best adhesion of the preservatives while the wood cell is open. Topcoating in dry interior conditions ensures that there are no contaminants under the paint surface that could damage the wood. Painted panels are dried in ovens, which ensures that the paint surface dries evenly and prevents cracking. The back surface of the pre-painted panels is also protected, which prevents any moisture that may condense from the building from being transferred to the back surface of the cladding panel.

2. Protects against water and pollutants

Pre-painted panels are manufactured for concealed panel formats. This way the fixing marks are hidden under the next panel and water cannot damage the wood from the fixing marks. When the fixing marks remain hidden, the end result is a beautiful, uniform wood surface. On facades with overhead nails, the nails will start to show after 3 to 5 years. The nail heads collect moisture and water begins to accumulate at the nail. Pre-painted panels do not need to be repainted after installation because the durable paint finish is not broken during installation.

Take a closer look at our two pre-painted and concealed cladding panels:

TOPCOAT exterior cladding panel, concealed with hooks

GOLD PRO exterior cladding panel, concealed with nails

3. Less material waste

In construction, time is money, but materials are not free either. End-jointing pre-painted cladding panels ensures that waste during installation is kept to a minimum. End fitting allows the panel extensions to run naturally along the panel surface, rather than having to be aligned with the fascia boards. There is minimal wastage in the end-jointed panel because the piece that is left over from the previous row can be used to start the next row. Without end-jointing, up to 10 panels out of 100 are lost, while with end-jointing only 1 to 3 panels out of 100 are lost.

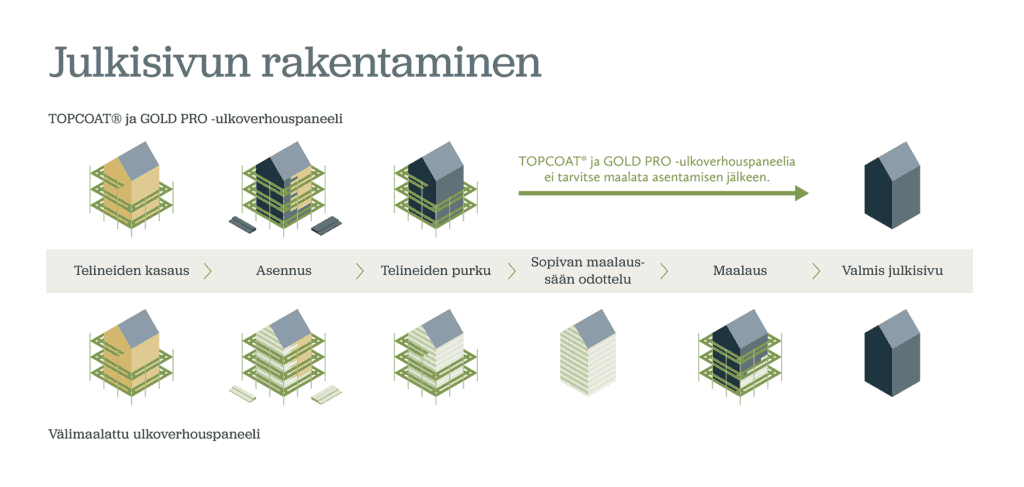

4. Savings on construction costs

When pre-painted cladding panels are used, the biggest savings for the builder come from the elimination of painting costs. With pre-painted panels, a finished façade is built immediately and does not need to be repainted after installation. The benefits include time savings and the fact that installation can be carried out in late autumn or even in winter. Next summer, there is no need to hire and erect scaffolding again and wait for suitable weather and painters to paint. All you need to do in 10-20 years is to do any maintenance work.

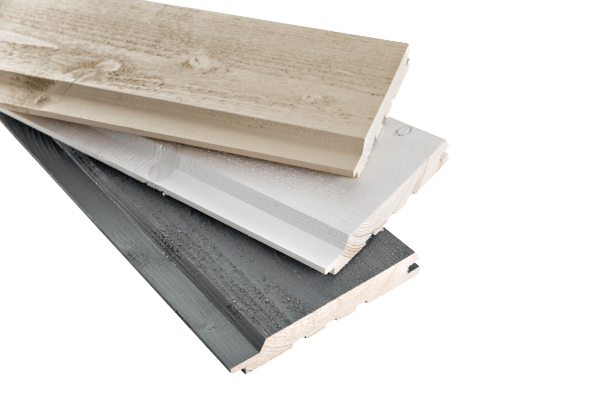

5. Attractive shapes and shades

The façade is your home's calling card, and its design and implementation must be done with care. When choosing an exterior cladding panel, it's a good idea to start by considering whether you want to install the panels vertically or horizontally. Vertical cladding emphasises the height of the exterior wall, while horizontal cladding emphasises the width. The width of the cladding panel can also influence the appearance of the façade. The width of the cladding panels can vary from 95 mm up to 280 mm. The choice of the colour of the panel also plays an important role. You can choose a opaque or a durable shade for the wood. There are 6 different options for durable shades and hundreds of different colours for opaque shades.

6. Guaranteed quality

Pre-painted TOPCOAT® and GOLD PRO exterior cladding panels have been manufactured for more than 10 years. They have been used to clad both large public buildings and private homes. We offer a 10-year guarantee on our pre-painted exterior cladding panels. Our panels' concealed fasteners improve the durability of the façade and the industrially applied layers of paint provide long-lasting protection against the sun's damaging UV rays.

Remember that the durability of a facade can also be improved by architectural choices such as the length of eaves. The guarantee is conditional on the panels being correctly installed and registered on our website. The warranty period for TOPCOAT® panels can be extended to 15 years with one additional industrial painting.

Read the warranty conditions for the TOPCOAT® hook and loop panel for external cladding

See the warranty conditions for the GOLD PRO nail-fixed external cladding panel

How to install a concealed panel?

To achieve a completely nail-free façade, the installation of concealed panels starts with the initial hooks. The first row of panels is placed on top of the starting hooks and subsequent rows of panels are fixed in the normal way by shooting the panels into the pots with nails or hooks. TOPCOAT® panels are recommended to be fixed with hooks. This ensures that the fixing marks do not become visible as the width of the wood changes with seasonal moisture conditions. The shape of GOLD PRO panels allows them to be fixed with traditional nails. The fixing marks of both panels remain hidden and do not completely break the finished paint surface. See how to install a concealed panel