Rainy summers in recent years have disrupted builders' schedules and compromised the quality of exterior painting. Short exterior painting seasons increase the cost of façade work, as everyone grabs their brushes at the same time. Exterior painting has traditionally pushed back the completion schedules of construction projects. Pre-painted cladding panels free construction from seasonal constraints.

- From the builder's point of view, it's nice when the cladding is done all at once. We've made big savings by not having to get up on the scaffolding once on site. For example, we can immediately halve our personnel lifting costs," says Arttu Suuronen from JVR-Rakente, the construction contractor for the Puukuokka block.

Weather is always a factor of uncertainty in Finland. With pre-painted TOPCOAT® panels, a building can be completed at any time of year, even in winter. In the spring, you can start work on the courtyard immediately, without having to wait for the facade to be painted. A one-step exterior cladding process speeds up schedules and streamlines the overall construction project.

Unnailed wooden facades in Jyväskylä's Puukuokka block

In all three apartment buildings of the Puukuokka block completed in Jyväskylä in summer 2018, the exterior cladding is made of pre-painted, concealed Topcoat® exterior cladding panels. The façades are clad with black painted cladding panels and larch cladding. Exterior cladding panels painted in dry and stable factory conditions ensure that the wood is sufficiently dry and the paint film is allowed to form in optimum conditions, unlike exterior painting sites at the mercy of rainfall.

- On facades that are nailed from the top, the nails will start to show after 3-5 years. The nail heads collect moisture and water starts to accumulate at the nail. Concealed fixing of panels is a viable solution for façade maintenance. The nail heads are not visible, which prolongs the durability and maintenance life of the facade," says Suuronen.

Topcoat® exterior cladding panels have a 10-year guarantee on the painted surface. The warranty requires that the panels are correctly installed and the cut-off surfaces are painted to ensure the long-term durability of the wood.

Less wastage allows savings in construction

The installation of a pre-painted cladding panel requires careful workmanship, as it is a finished surface. Otherwise, the installation of concealed cladding is no different from the installation of traditional cladding.

- By cladding the exterior with pre-painted, prefabricated panels, the amount of scrap material is reduced, allowing for a more economical and ecological construction. This is also very much in line with the principles of timber construction. After all, the goal of timber construction is resource and energy efficient construction," says Olli Prättälä from Siparila.

Smooth facade finishing

After the façade surfaces have been installed, the finishing work begins, such as the panelling of the window sills, the moulding of the corners and the fascia boards that define the roof. Finishing must be done carefully to prevent water from entering the structure.

- To help builders, Siparila has developed custom-sawn smyth boards and a quick-fit aluminium strip that allows the boards to be easily placed in position. The boards are surface painted on three sides and require only a quick finish coat to cover the fixing marks. Even problematic crooked windows can be tightly finished with our smythgiris solution," says Prättälä.

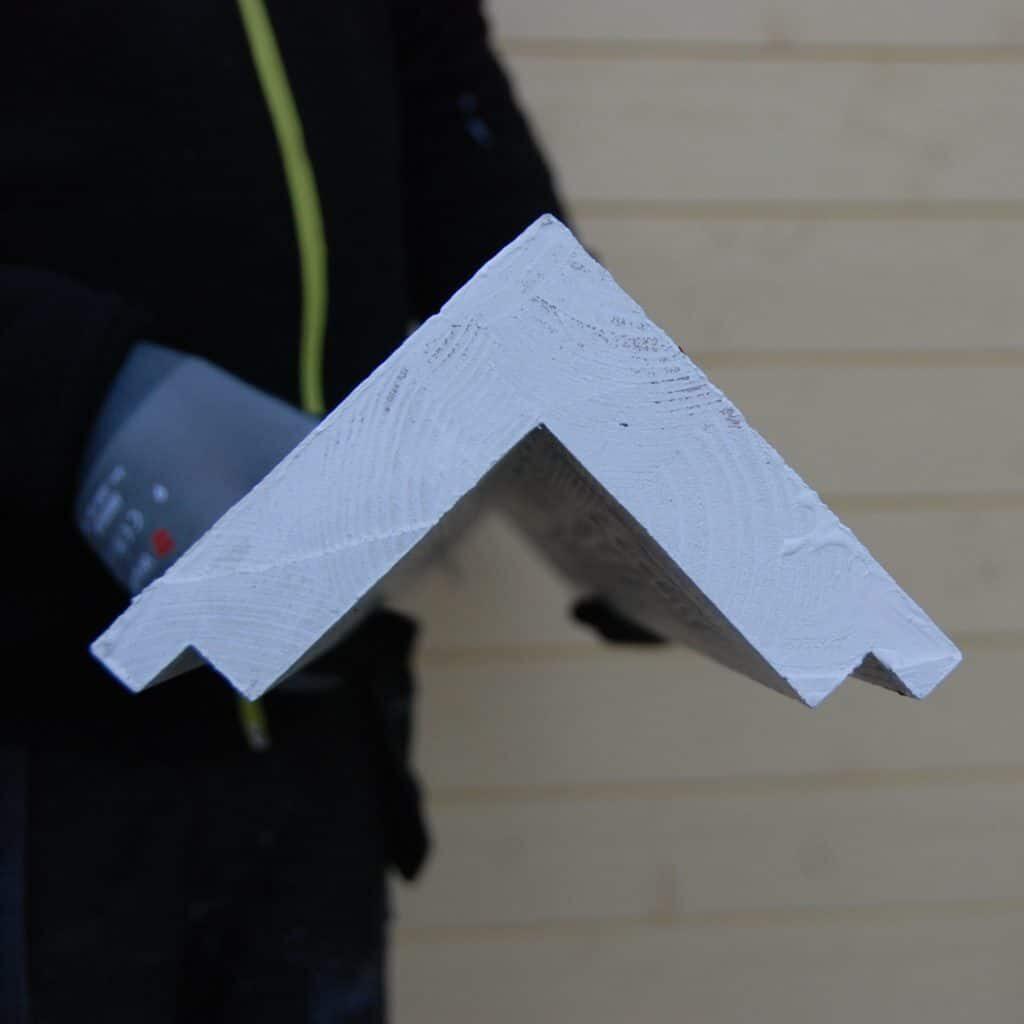

Nowadays, corners can also be created with fully prefabricated corner elements and there is no need to fiddle with loose boards on site. The advantage of corner elements is that corners do not start to grimace over time like corners made of loose boards. All finishing products are surface painted, which speeds up construction and gives the finished product an instantly finished look. In addition to the panels, corner and smyth mouldings were also ordered for the Wooden Class block.

- Siparila and I had a good spirit of working together. The details of the building site were discussed before the start of the project and, in addition to the panels, the corner and smyth boards were delivered to the site, ready painted, within the agreed timeframe. This meant that the site was not overflowing with building materials and the products did not have to lie around in the weather," says Arttu Suuronen of JVR-Rakente.

Read a more detailed project description of the construction of the Wooden Classroom here.

Summary of the benefits of TOPCOAT cladding panels

- Pre-painted panels do not need to be surface treated on site after installation

- Reduced staff purchasing costs, no surface painting costs

- End-jointing of panels reduces waste and reduces waste volumes

- Building project can be completed all year round

In 2008, Siparila developed the concealed, pre-painted Topcoat®-cladding panel. The panel has been used in demanding architectural projects and large-scale timber construction, including the Haltia Nature Centre in Espoo, the Myllypuro timber city area and the Ell campus in Joensuu. Topcoat®-panels are also exported to Canada and the Netherlands.

Pre-painted corner element for faster facade finishing